Advanced Thermal Solutions

Reduced-Scale Hotbox System

Design and development of accurate thermal property characterization method for energy-efficient building materials.

Year:

2019

Affiliation:

- University of Boulder Colorado

- Norwegian University of Science and Technology

- SINTEF Industry

- SINTEF Building and Infrastructure

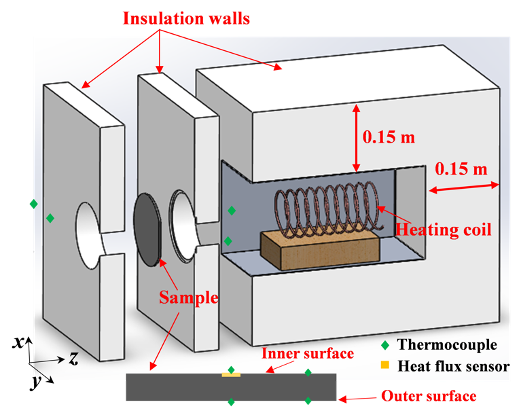

Schematic illustration of the reduced hotbox-system. The heating coil is used to control the temperature inside the chamber. The thermocouples are used to monitor the surface temperatures of the specimen, insulating walls, air temperatures inside the hot chamber and the room environment. A heat flux meter is used to measure the heat flow through the specimen.

Accurate characterization of thermal properties including thermal transmittance (U-value) and thermal conductivity (k-value) is key for design, evaluation, and adoption of new generation of materials, e.g, nano insulation materials, transparent porous insulation materials, used for energy efficiency applications in buildings. The U-value and the k-value are the two parameters used to select the type and thickness of insulation materials and evaluate economic performance in the building construction/renovation industry. Therefore, developing a convenient tool that can be used to characterize the thermal transmittance and thermal conductivity of desired nanostructured materials with much smaller sizes (e.g. 0.2 m × 0.2 m) in real environment, especially during early stages of material development when large size samples are not yet available is highly required and desired. To achieve that objective, reduced-scale hot box system (RHS) that can accurately measure the U-value and k-value of nanostructured materials with sizes ranging from 0.06 to 0.2 m (diameter or length) for both circular and square shapes under varying circumstances, considering humidity, wind, and temperature was designed and developed.

The overall dimensions of the hot box are 0.5 m × 0.5 m × 0.6 m (x–y–z directions). The insulating walls are built using commercially available extruded polystyrene foam (XPS, ~ 0.035 W/(mK)) with a wall thickness of 0.15 m. The inner chamber dimensions are 0.2 m × 0.2 m × 0.35 m (x–y–z directions) to provide easy access to the inner components such as sensors and the heating coils. The specimen is placed in the opening of the chamber, which separates the hot chamber from the cold room environment. Fourteen (14) T-type thermocouples (Omega, accuracy ± 0.5 °C or 0.4%) are used to monitor the surface temperatures of the specimen, insulating walls, air temperatures inside the hot chamber and the room environment. A heat flux meter (HFM) with dimensions 3.0 cm × 3.0 cm × 3.0 cm (greenTEG gSKIN®-XO, ± 3%) is used to measure the heat flow through the specimen, in which opposite to the conventional hotbox case avoids the parasitic heat loss on the measurement accuracy. The thermocouples and HFM are connected to a multiple channel data acquisition system (National Instruments, NI-9213). The measured temperatures and heat flux are recorded by LabVIEW software. The temperature inside the chamber can vary from room temperature to ~ 80.0 °C. The room temperature is set to be the cold chamber temperature. The humidity level is controlled using a simple humidifier inside the hot chamber. Three sensors, each placed within the chamber, outside the chamber and in the room environment, respectively, are used to monitor the temperature and humidity. The wind speed (convection) is set using a fan perpendicular to the outer surface of the specimen. The specimen’s surface emissivity is measured using infrared (IR) camera (T630sc from FLIR). Commercially available materials with known thermal properties as well as Laser Flash apparatus method were used to compare and calibrate the RHS system, confirming that RHS is a simple yet very effective technique to accurately measure thermal properties of nanostructured materials with small sample sizes. The established measurement method can facilitate the development of next generation of novel materials for energy-efficiency building applications