High-Performance Thermal Insulation Materials

Hollow Silica Nanospheres

Design, synthesis, modeling & characterization of hollow silica nanospheres for thermal insulation applications in energy-efficient buildings.

Year:

2020

Affiliation:

- University of Boulder Colorado

- Norwegian University of Science and Technology

- SINTEF Industry

- SINTEF Building and Infrastructure

- University of Vermont

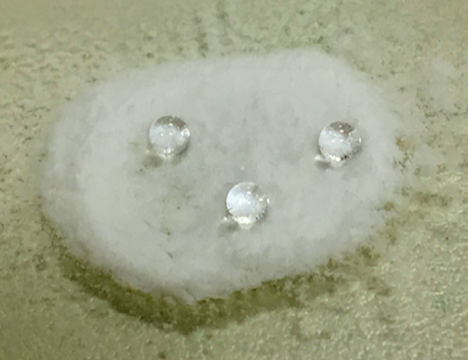

Hydrophobic Hollow Silica Nano sphere powder covered with water droplets.

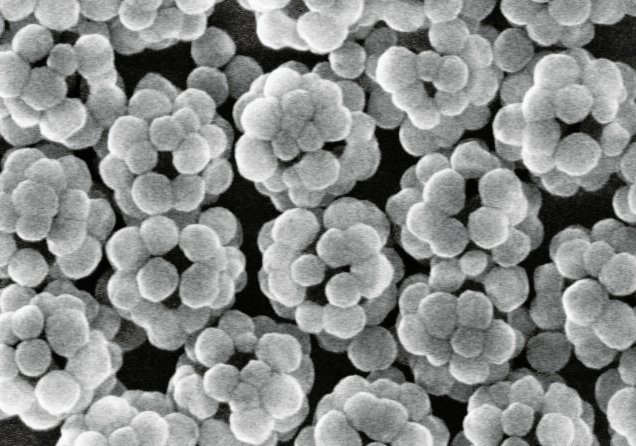

Scanning Electron Microscope (SEM) image of HSNS assemblies with inner pore diameter ~85 nm and shell thickness ~ 30 nm.

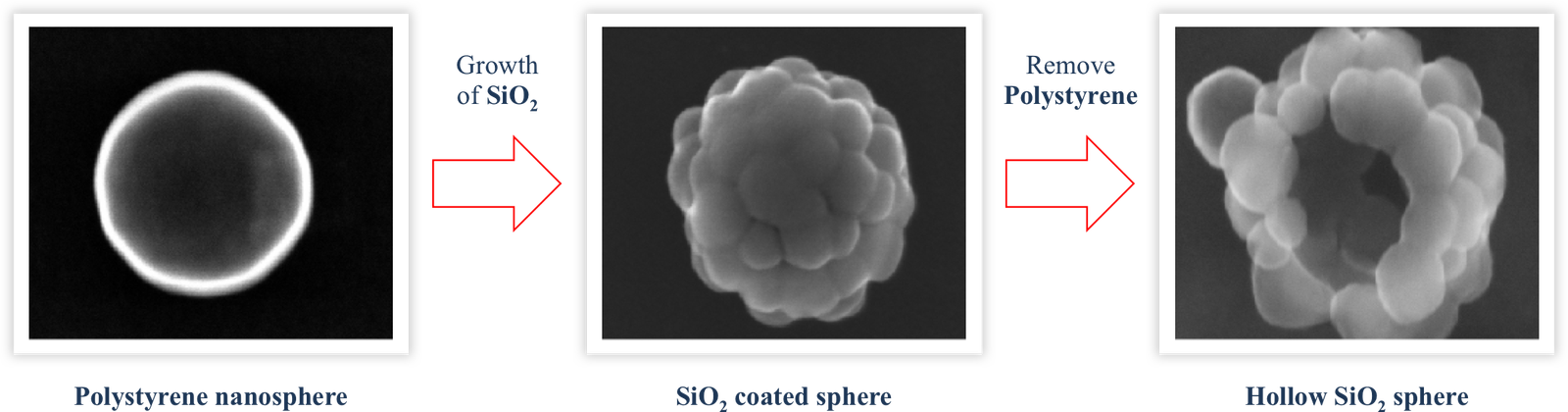

Hollow silica nanospheres (HSNS) have garnered much attention due to their unique properties such as low density, high porosity, large surface area to volume ratio and encapsulating ability, which have led to significant advances in applications for biomedical, electrical, and construction sectors. HSNS provide noticeable advantages to explore for miscellaneous thermal insulation applications. Distinctive advantages of HSNS for thermal insulation applications are amongst others, their controllability, i, e., thermal properties of HSNS being promptly modified by utilization of their structural characteristics, such as inner pore diameter and shell thickness. In general, HSNS can be classified as an air cavity enclosed by an inorganic shell with tailored structural features, where the voids are usually correlated to the use of sacrificial templates during the synthesis of HSNS.

The inner pore size of HSNS can be readily controlled by using the templates, e.g. polyacrylic acid (PAA) or polystyrene (PS), with different dimensions; the shell thickness of HSNS can be adjusted by a controlled growth and deposition of silica nanoparticles; and the shell morphology, depending on the reaction conditions, may be dense or porous. Our study validated the size-dependent thermal conduction at the nanoscale and demonstrated that HSNS assemblies yield thermal properties intermediate to those of gas and solid by tuning the structural parameters, i.e., inner pore diameter and shell thickness. By capitalizing on the apparent structural features of HSNS, we have recorded the lowest thermal conductivity value 14 mW/(mK) for HSNS with inner pore diameter 85 nm, shell thickness 30 nm, density 0.19 g/cm3 and ~ 90 % porosity. Furthermore, essential issues concerning life cycle assessment, hydrophobic treatment and environmental friendliness were investigated to enable HSNS as the potential target for superinsulation materials used for building thermal insulation applications.